Once Lid is cut from battery, there is Lead casted

Pole/Post molded in Lid. This Pole can be extracted from Lid. Pole

Extraction Machine will be used for this purpose.

This machine is fitted with interchangeable die. This die can changed by

pick & place technique. This machine is pneumatically operated and

initiated by Pedal Valve. Cut Lid is placed on die and machine is operated

by pressing foot on valve. Top punch presses Pole out of Lid. This can be

seen in the video. Now, Lid will be with-out Lead parts. Of course, Lead

parts will be having bit of Plastic in which it is molded. This Plastic can

be ignored.

Cut Strap & Plastic Container strip held

together will separated by this machine. This machine is pneumatically

operated and initiated by Pedal Valve. Cut Container Strip with Intercell

connections is placed on machine, Partition will be placed on centerline and

fork arm will be across it. It is operated by pressing foot on valve. One

fork will press against another and connection will break. This can be seen

in the video. Now, Cut Container Strip will be with-out Lead parts.

This is Required to supply pressurized air to above

mentioned Two machines. Required Power: 415V 3 phase, 2.25 Kw approx.

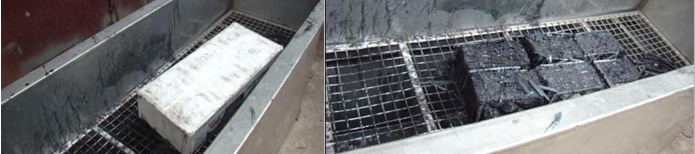

Once Battery is cut and now only Plates with

separator are there in Plastic container. There may be acid in the Battery

Container still. Battery will drop in upside position, manually assisted.

Container can be picked up and placed at a side or drop in Plastic Crusher.

Battery Plates and Separator can be dropped in Plate Crushing Machine. Acid

will drop in tank. Acid Proof Tank is in-built in the attachment. Lead Oxide

Dust and small grid parts will precipitate. Acid can be pumped out, if

connected to another tank. Lead Sludge can be charged in furnace.