We manufacture Battery Breaker. Now, We have made

Battery Cutting Machines. Speed of cutting is 5- 7 Batteries/Minute for

small smelter.

This machine has a automatic conveyor. Battery is

placed on the conveyor. Width of Battery, need not to be set. It can

accommodate Battery up to Max. Width of 305mm. Most of Batteries are below

this. Cutting height can be set by turning Rotary wheel. This wheel is

visible in picture of machine. Scale is provided to set the height of

cutting from bottom. Conveyor takes the Battery in machine for cutting.

During Cutting of Battery dust is confined inside of covers because cutter

is enclosed. Normally Cutting is set at sealing line of lid. Max. of

Automotive Batteries have approximately same height, say +-10 mm. Remaining

Battery will come out of machine on Conveyor.

This saves exposure of workman from Lead Dust; increases efficiency of

organization reduces lead time as well as increases liquidity of Funds.

Plastic Containers can be sent for immediate disposal/recycling facility.

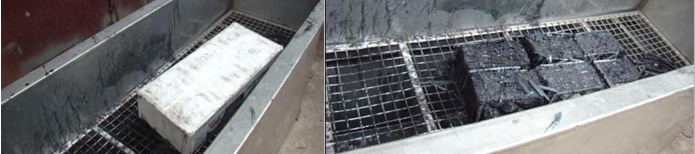

Lead Dust is confined inside enclosure at the same time water jets are

provided by pre-fitted Pump. Water is collected in the bottom tank. This

helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead

dust is precipitated at the bottom. Hence it becomes environmentally Sound

Method to cut the Battery for further separation. Remember this Cut Battery

can directly go to another attachment; we call it Acid Draining Attachment.

Details of this attachment are mentioned below.

This machine is suitable for small quantity of

Batteries, Battery Assembly Lines or very less budget.

Power required: 415V 3 phase, 4 Kw approx.

Belt made of : Nylon

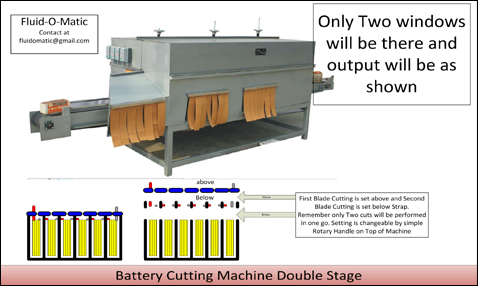

This machine has a automatic conveyor. Battery is

placed on the conveyor. Width of Battery, need not to be set. It can

accommodate Battery up to Max. Width of 305mm. Most of Batteries are below

this. This machine has two Blades for Cutting. Cutting heights of both the

blades can be set at independent height by turning Rotary wheel. This wheel

is visible in picture of machine. Scale is provided to set the height of

cutting from bottom. Conveyor takes the Battery into machine for cutting.

First cutting is set normally at sealing line of lid and Second cutting is

set below strap. During Cutting of Battery dust is confined inside of covers

because cutter is enclosed. Max. of Automotive Batteries have approximately

same height, say +-10 mm. Cut Lid ejected out of first window and Strap

portion of battery ejects out form second window. Remaining Battery will

come out of machine on Conveyor. Machine can be provided with wheels so

machine is used to unload battery at the same time cutting is performed.

This saves exposure of workman from Lead Dust; increases efficiency of

organization reduces lead time as well as increases liquidity of Funds.

Plastic Containers can be sent for immediate disposal/recycling facility.

Lead Dust is confined inside enclosure at the same time water jets are

provided by pre-fitted Pump. Water is collected in the bottom tank. This

helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead

dust is precipitated at the bottom. Hence it becomes environmentally Sound

Method to cut the Battery for further separation. Remember this Cut Battery

can directly go to another attachment; we call it Acid Draining Attachment.

Details of this attachment are mentioned below.

This machine is suitable for normal quantity of

Batteries or by small smelter with normal budget.

Power required: 415V 3 phase, 8 Kw approx.

Belt made of : Nylon

This machine has a automatic conveyor. Battery is

placed on the conveyor. Width of Battery, need not to be set. It can

accommodate Battery up to Max. Width of 305mm. Most of Batteries are less

than this. This machine has three Blades for Cutting. Cutting heights of all

the three blades can be set at independent heights by turning Rotary wheel.

This wheel is visible in picture of machine. Scale is provided to set the

height of cutting from bottom. Conveyor takes the Battery into machine for

cutting. First Cutting is set above lid so any battery which has more height

than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo

etc. will be cut and that portion ejects out from first window. Second

cutting is set normally at sealing line of automotive battery lid and third

cutting is set below strap.

During Cutting of Battery dust is confined inside of covers because cutter

is enclosed. Max. Of Automotive Batteries have approximately same height,

say +-10 mm. Cut Lid ejected out of first window and Strap portion of

battery ejects out form second window. Remaining Battery will come out of

machine on Conveyor. Machine can be provided with wheels so machine is used

to unload battery at the same time cutting is performed.

This saves exposure of workman from Lead Dust; increases efficiency of

organization reduces lead time as well as increases liquidity of Funds.

Plastic Containers can be sent for immediate disposal/recycling facility.

Lead Dust is confined inside enclosure at the same time water jets are

provided by pre-fitted Pump. Water is collected in the bottom tank. This

helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead

dust is precipitated at the bottom. Hence it becomes environmentally Sound

Method to cut the Battery for further separation. Remember this Cut Battery

can directly go to another attachment; we call it Acid Draining Attachment.

Details of this attachment are mentioned below.

This machine is suitable for normal quantity of

Batteries or by small smelter with normal budget.

Power required: 415V 3 phase, 12 Kw approx.

Belt made of : Nylon