|

|

|

Home »

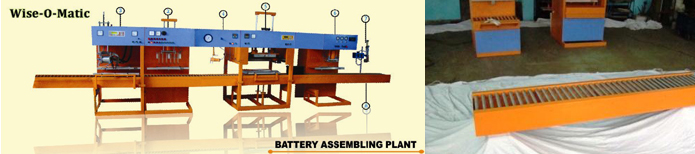

Our Product » Battery Assembling Plant No-1 (Line-O-Matic)

Details For Battery Assembling Plant No-1 (Line-O-Matic)

HOLE PUNCHING MACHINE (SINGLE HOLE IN ONE GO)

Application :- This machine punches Single

hole at a time in partition of container. Machine is pneumatically powered.

Different size of hole can be done with the help of different die for

different size of batteries. Three Dies will make five sizes of batteries.

Operation :- Place the container in upside down position to fit

required slot. To punch five holes, five operations are required to be

repeated. Different die is required to suit different size of battery

container.

- Capacity :- 40 containers/ hour.

- Air consumption :- 0.07 Cubic Foot/ stroke at 70PSI or 5

Kg/cm²

- Manpower Requirement :- One Layman

INTER PARTITION WELDING MACHINE (Stand Alone Model)

Application :- This machine connects cells

through the partition of container.

Operation :- This Machine forges L- connecter of cells through the

hole of partition together and passes heavy current at low voltage so

portion of these connecter through hole of partition melts, taking advantage

of resistance of lead, and become single entity. This machine does mass

production and running cost comes to minimum, hence cost per battery is

reduced to minimum.

Major Specialties

Transformer :- Current source of Machine is

state of art heavy transformer of 65 KVA rating. We use best quality of

copper, which dissipates lesser heat. So machine does not waste Costly

electricity in the form of heat. Only Air-cooling is sufficient. If

water-cooling is used it will increase running load of pump and wastewater,

which has also becoming precious and harming the environment so our machine

is environment friendly. At the same time reducing running cost of machine.

Welding Computer (Micro Processor based Controller) :- It is

designed indigenously as per need of our operator. This computer supply

constant energy at constant current. Welding processes & parameters are

controlled automatically & accurately by specially designed

microprocessor. Operator can program 10 programs for different batteries.

All parameters such as Squeeze Time, Weld Time, Cooling Time and required

Current as per battery size, are fed to controller for battery size and

recall whenever that size of battery is made. Operator can also see which

operating time has been lapsed which other controllers do not provide. He

can also communicate if any of the problems so he could be guided directly

without physically present on the machine. If any type of problem arises it

can be replaced/ repaired at nominal cost even after warrantee period.

Welding Heat adjustment :- This controller is specially designed to

suite lead melting say 250ºC to 700ºC, this bend is divided in 99

digits setting, unlike imported Controllers i.e. Miyachi etc which has

controlling temperature from 50ºC to 3000ºC this bend is also

divided in 99 digits setting, so operator does not get accurate results.

This results in faulty connection without consistency. Welding Heat

Adjustment: 0 to 99%, Welding Time Adjustment: 0 to 99, All are digital

Display.

Double Arms Movement :- For forging, we have designed better Forging

Head. This head has double arms movement and self-centering arms.

Man Power Requirement :- One Operator.

Power Requirement :- 20Kw, 2Phase.

AUTOMATIC HEAT SEALING MACHINE (Stand Alone Model)

Application :- This machine seals Lid to

Container. For every size of container you require Separate sealing fixture.

Operation :- Battery has to be pushed to

other machine manually. Battery has to be placed from Front & pulled to

get battery out from machine. Hot Plate has two different temperatures to

melt cover & container respectively. Fixture is required to hold top

cover for melting & sealing. This machine is having heavy structure to

suit faster production and longer life.

Self-setting fixture :- Fixing of fixture is so easy that a layman

can do job. Change -over time is less than Fifteen Minutes.

Hook (Clamping) System :- We use hook system (Positive Locking) to

pick lid, so it is everlasting, no recurring expenses like Vacuum cups which

require changing of vacuum cups & consuming electricity for operating

vacuum pump which has to be maintained properly and finally replaced after

sometime.

Faster operation :- Operation of machine

take lesser operating time, hence output is increased. Moreover interval,

between Lid melting and pressing it with container, is reduced to minimum.

Otherwise melted portion of lid will be having cooled layer which will

increase chances of Leakage. This feature of our machine gives Best Sealing.

Dual Temperature (Different Temp. for cover & Container) Hot Plate

:- Hot plate for this machine is having auto dual temperature to seal

leak-proof.

Capacity :- 50 Batteries/hour of any size.

Electrical Power Requirement :- 415Volts to 380 Volts, 10Kw.

Heat Temperature :- 400 º C is adjustable depending on Plastic

materials used in container.

Compressed Air Power :- 0.09 Cubic Foot / stroke at 120 PSI or 8

Kg/cm²

Man Power Requirement :- One Operator.

HEAT SEALING FIXTURES

STRESS TESTING MACHINE (Auto Electro- Pneumatic)

Application :- This will check strength of

welded connections torsion strength by applying mechanical force across

connections.

Operation :- Fingers has to put manually

across connection so it is able to apply Force on one connection against

other this force can be varied depending on connection size or size of

battery, if that connection is hollow it will break. The time to apply force

is determined by Digital Timer so force as well time to apply force is

precisely preset hence result become accurate.

Capacity :- 80 Battery/hour.

Force :- 785 kgf. Adjustable

Man Power Requirement :- One Layman

AIR LEAKAGE TESTER (MANUAL MODEL):

Application :- This machine checks air

leakage in One cell of the battery in one go. Leakage of Cells can be

watched on respective Pressure Gauges which is provided.

Operation :- Place the Leakage Tester on

every Battery’s cell and fill a certain air pressure according to the

battery size. After that it checks the air leakage on particular cell so

getting fool proof result of getting the leakage in particular cell. After

this cycle finishes, repeat the same with rest of the cells.

Capacity :- 50 Batteries/hour.

Testing Pressure :- Adjustable from 1 PSI to maximum as per battery

sizes (Max. 6PSI for N200).

Testing Time :- Depending on operator (5 seconds to 15 Seconds).

Man Power Requirement :- One Operator.

SHORT CIRCUIT TESTER (ONE CELL IN ONE GO)

Application :- This machine checks pin hole,

separator missing and splash of lead in cells, etc. It also checks that all

the cells are connected to each other with the help of high voltage. If

there is any fault then it gives visual indication as well as audio alarm.

Operation :- Operator has to place the Battery underneath the

machine and press the button on its Probe, which initiates machine that does

its job for One cell in one go.

Capacity :- 40 Battery/hour.

Man Power Requirement :- One Layman

Conveyor (5 Mtrs)

SERIAL NO. PUNCHING MACHINE (AUTOMATIC)

Operator need not to change punches daily. Operator

has to press a push button, which initiates pneumatic cylinder for a set

period so hot punches are pressed at set temp. For the set period with a set

force to mark the exact depth on battery cover.

This machine is more accurate. Every Battery

manufactured will have distinguished Mark on it. It can be alphabetically or

numerically or Combination of both. Number of Punches can be Six/Eight/Ten

or as per requirement of individual Manufacturer.

Plant No-1 (Line-O-Matic)