|

|

|

Home »

Our Product » Acid Draining Machine

Acid Draining Machine

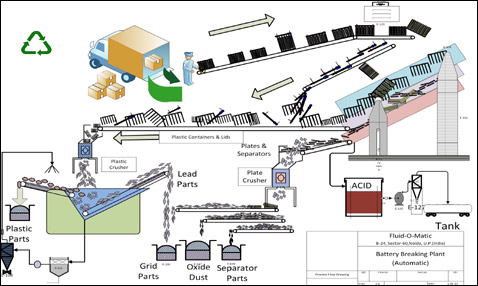

Batteries are loaded on battery feed conveyors and

it passes through Acid Extraction/ Draining machine that is mounted on FEED

CONVEYORS. Acid is automatically drained out from battery & acid is sent

to its storage tank. Acid stored in a tank, the precipitated oxide slurry is

taken out with the valve & the acid is sending for Recycling.

(Conveyorised)

Once Battery is cut and now only Plates with

separator are there in Plastic container. There may be acid in the Battery

Container still. Battery will drop in upside position, manually assisted.

Container can be picked up and placed at a side or drop in Plastic Crusher.

Battery Plates and Separator can be Transported to Plate Crushing Machine.

Acid will drop in tank. Acid Proof Tank is in-built in the attachment. Lead

Oxide Dust and small grid parts will precipitate. Acid can be pumped out, if

connected to another tank. Lead Sludge can be charged in furnace.

Acid Collection & Filtration Unit

Acid stored in a tank, the precipitated oxide slurry

is taken out with the valve & the acid is sending for Recycling:

Neutralization. It can be handled in two ways: First way, the acid is

neutralized with an industrial compound similar to household baking soda.

Neutralization turns the acid into water. The water is then treated;

cleaned, tested in a waste water treatment plant to be sure it meets clean

water standards. Second way, the acid is processed and converted to sodium

sulfate, an odorless white powder that's used in laundry detergent, glass,

and textile manufacturing.

Battery Cutting System

Conveyor can be connected to the Lorry which

carrying the Scrap Batteries to have lesser manual shifting of batteries. It

is an additional requirement which is chargeable at additional costs. It is

integral unloading and feeder to Lid Shaver Machine. We shave the Battery

from under its cell straps. Proper Cooling Arrangements are made, that

enhances the machine's life so the cutting equipment gets cool at the time

of cutting battery's lid parts. Now, the shaved lid which is separated from

under the welded straps is sent through conveyor to Lid Crusher Machine.

Parts Separation Machine

The Lid part is completely crushed and sent to

Lead-Plastic separating Machine: i.e., Metal Classifier; with this process

plastic parts are separated from the Lead parts. Such plastic parts are sent

to the Plastic Crusher & are cut into smaller pieces. The Rest

of the battery is moved on conveyor to the PART SEPARATOR MACHINE &

all the parts are separated totally and sent to their separate respective

storage tanks with the help of Conveyor systems. This separation machine is

enclosed & no dust particles come out of the plant this increases plants

recovery & reduces wastages of material. For dust collection BAG HOUSE

is attached so that the oxide dust is stored in a filter bag. In this

machine, on the First stage, the Battery Casings are taken out & sent to

their separate section through its connecting conveyor. Later on, these

Casings are sent to the same earlier Plastic Crusher, or a separate crusher

can be placed as per customer's choice at additional cost which depends upon

the Production capacity of the plant.

After this step, the Plates & Separators are sent to the second level,

in this section using a particular stage of vibration resonance at certain

level we have taken out maximum quantity of Lead parts from the Plates &

Shredded oxide material on the Third stage for Collection in its particular

storage tank. In this stage, we took out the impregnated material from the

plates on Grid. The rest material on plates are taken out with Battery

Separators are sent to the Part Separation Machine on which the Plates are

separated on one stage i.e., on one side & Separators are stored on

other side. The Plate Parts & Separator Parts are separated and here we

are collecting the rest of the shredded oxide material. The Grid parts &

separators are separated by using the Grid-Separator Separation Machine. In

this machine, Both Grids parts & separator parts are dropped through

conveyor. Heavy air & water pressure is given simultaneously in the

machine and by using floatation method we are separating the Separators &

Grid Parts. These shredded Plates are sent to the FURNACE FOR SMELTING

[Recycling]. And the Separators are sent through conveyors to A Separator

Washing Machine. This separator washing machine is added to the system as

per the customer's on demand or as per the plant production capacity. The

machine is completely enclosed and environment friendly. Getting back on

Parts Separation Machine, in the third layer of separation, Broken Separator

Parts, Broken Grid Parts & Oxide Dust is taken out & sent to the

other Metal Classifier & Floatation Tank is attached on that. In this

section, Separator parts floats in water tank. The Lead Parts & the

Oxide dust is settled down on the bottom side of the tank due to its weight

& taken out with the help of rotary valve. And, the same water can be

used again & again. The transferring of Lead Parts & Oxide Dust

material can be sent to their respective Refining Pots & Smelting Units

through Fork Lifts/ automatically with the help of automated mechanized

system that will be on customer's demand at additional cost.

Plastic Crushing Machine

The shaved lid which is separated from under the

welded straps is sent through conveyor to Lid Crusher Machine. Plastic parts

are separated from the Lead parts. Such plastic parts are sent to the

Plastic Crusher & are cut into smaller pieces. This machine is used to

crush Battery Container made of Plastic Material. It crushes to small Pieces

up to size of 1" square in one go and Washes Lead accumulated on it. It

is shearing & hammering action increases its Power versus Output Ratio.

Lead is precipitate on another conveyor. This conveyor conveys Lead

Particles/ Pieces to one side. Plastic which can float on water will be

filtered on another Conveyor. Plastic is fed to Plastic Washing Machine.

This Plastic Washing Machine washes Plastic with Soap Solution. Plastic is

filtered and collected. Water is used again after purification.

- Total Power: 56 H.P./42Kw.

- Container Feeding Conveyor: This conveyor is used for feeding Plastic

- Container to Plastic Crusher: M.S. material makes. The Drive of

Electrical, 415V/380V, 3 Phases, 50Hz, 0.5 HP

- Crushed Plastic Feeding Conveyor: This conveyor is used for feeding

crushed plastic to Plastic/ Lead Separation Machine; It is of MS

material.

Plastic Washing Machine

The crushed plastic is sent to Plastic Washing

Machine through Feed Screw Conveyors to Floating Washing Machine. The

plastic is washed & lead Contents sinks to the bottom of machine, the

plastic is simultaneously forwarded ahead to the hot washing machine. Then

the plastic is taken out with the help of Screw Conveyor from other end &

put up in centrifugal de-watering machine, the washed plastic is taken out

with the blowing system through Blower. The washed clean plastic is then

stored in a storage bunker from there the material can be stored in bins or

sacks. The machines are included in system are:

- Feeding Screw Conveyors

- Floating Washing Machine

- Hot washing Machine

- De Watering Machine

- Air Blown Pipeline

- Blower Fan

- Storage Bunker

[The size of the machines are designed according to their

production capacity]

Separator Washing Machine & Lead Paste Filtration Unit

A Separator Washing Machine; This separator

washing machine is added to the system as per the customer's on demand or as

per the plant production capacity. The machine is completely enclosed and

environment friendly. The separators are fed to the machine through Screw

Conveyor from one side & washed in the machine & are taken out from

other end. The lead contents sinks & taken out with the help of rotary

valve & stored in a storage pit. The Lead paste is then filtered &

De-suphurized with the Desulphurisation Unit.