| Machine Particular Details |

1 Stage |

2 Stage |

3 Stage |

| Production Capacity / Shift |

Upto 50 MT [7~ lO Batteries/ Min] |

| No. of Cutting Blades. |

1 |

2 |

3 |

| Overall Area regd (L*B*H) In ft, |

(7*4*6) |

(8*4*6) |

(17*4*6) |

| Life Of Each Blade |

350MT |

| After Resharpening Same Blade |

50MT |

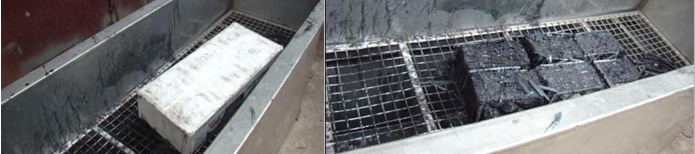

| Cutting Size/ At A Time |

ONE SIZE |

28AH -200AH |

28AH - 200AH & UPTO BATTERY HEIGHT OF 490MM |

| Cutting Stages At A Time |

From One Position |

From Two Positions: Below Battery Cover &

Under The Plate Connecting Strips |

Cut the battery from two sides of all sizes:

below the battery top cover & under The battery plate connecting

straps. Battery size above 200ah will cut from three height size

|

| Power Connection Reqd.[Kw./3Phase] 440Volts |

4.5 |

8.5 |

12.5 |

| Height Setting Guide Scales |

2 |

3 |

4 |