|

|

|

Home »

Our Product » AIR POLLUTION CONTROL SYSTEMS

AIR POLLUTION CONTROL SYSTEMS, GAS NEUTRALISING SYSTEM & GAS

STACKING UNIT REFINING POTS/KETTLE

Based on the parameters and the standards

mentioned, the following technology is adopted for Air Pollution

ControlSystem in Rotary Furnace:

- Rotary Chamber

- Gravity Chamber

- Involutes Cyclone

- Pulse Jet based Bag House Filtration System

Apart from plates and paste of lead oxide from scrap

batteries, slag from Mini Blast Furnace is charged in the Rotary Furnace.

In addition to these, certain compounds of sulphur are also present in the

batteries. When this material is heated in thePresence of carbon, lead oxide

is converted to lead. This conversion along with burning of fuel generates

flue gases and fumescontaining dust, dirt, oxides of lead, lead particles

and such other impurities etc.

Hence, to meet various goals of maintaining employees' health and factory

environments as well as regulatory requirements,it becomes imperative to get

high end Air Pollution Control Systems to be installed with the Rotary

Furnaces.

Rotary Chamber receives very hot gases from Rotary Furnace while cold gases

from atmosphere are induced into chambervia specially designed profile. Thus

chamber works as an equalizing chamber to reduce the temperature of gases

and alsowhere sedimentation of dust particulate matter takes place.

Rotary Chamber Advantages

- Recovers 100% lead in the first operation.

- Slag produced is lead free.

- Equipment can be scaled up for higher production capacities.

- Many chemicals are required for operation.

- High power consumption.

Rotary Chamber Disadvantages

- Difficult to produce low Antimony lead suitable for soft lead

purposes.

- Fugitive Emissions need to be captured in addition to flue gases.

- Need skilled operators and careful maintenance.

Fugitive Emissions Control Device

Smelting of lead in furnaces involve stages or

parts where though pollution is generated, it is not handled by the main

AirPollution Control System, like charging of Rotary Furnace when it is red

hot or tapping of lead from Rotary Furnace which leadto generation of fumes.

Systems put in place to capture and treat these fugitive emissions as and

when they arise are called Fugitive Emission ControlSystem. Fugitive

Emissions generally lead to pollution of work atmosphere and jeopardize the

maintenance of ambient airstandards at the workplace. Hence, to safeguard

employee health, these systems are becoming mandatory world over.

Norms of Ambient Air which the Fugitive Emissions Control System helps

to meet are Parameter Approved Range Time Period

- PM (size < 2.5 micron) < 40 microgm/ Nm3 Annual Basis

- PM (size < 10 micron) < 60 microgm/ Nm3 Annual Basis

- Lead < 0.5 microgm/ Nm3 Annual Basis

- SO2 < 50 microgm/ Nm3 Annual Basis

- NO2 < 40 microgm/ Nm3 Annual Basis

- Allows large size particles to settle down

- Cools down temperature of flue gases

- Used as spark arrestor to entrap live or red hot particles.

Gravity Chamber

Cyclone is used to remove medium size particles

from flue gases stream. The treated flue gases are discharged from topand

dust is collected at bottom.

Involute Cyclone

It is used for final filtration of flue gases to

remove fine dust particulate matter using Pulse Jet Technology. Treated

gases fromall the bags are collected at top of bag house and passed through

ID Fan to exhaust the same through chimney. The dust iscollected at bottom

of hopper and is discharged.

Duct Pipelines & Bends

All bends and reducers are aerodynamicallydesigned

and have provision of manhole cleaning mechanism.

Bag Filtration System

Ducts and Bends are required to convey flue gases

from point of suction to final top of the chimney and connect with various

pollution control equipment like gravity chamber, cyclone, bag house, ID Fan

and chimney.

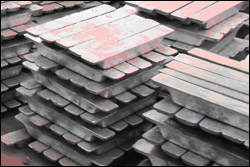

Jumbo Ingot Mould

Jumbo Ingot Moulds are collection trolleys used for

collecting molten lead from Rotary Furnaces. They can be of

varyingcapacities, ranging from 300 Kg. to 800 Kg. The most prevalent of the

same is 500 Kg. Ingot Mould. Due to higher weight of thecast, it is called a

These moulds have trolley type structure with two unidirectional wheels at

the back and one free spin wheel at the front. It isprovided with a handle

to pull it. They are moved manually or on rails electro-mechanically,

varying from unit to unit. They aresmoothened on the inside and do not have

any sharp folds or edges. They are usually constructed in SG cast iron for

longer life and increased strength.

Gas Neutralizing System for Air Pollution Control

Device: Wet Scrubber

A Wet Scrubber in the Air Pollution Control System

is mandatory in India and many parts of the world. Wet Scrubber uses water

to scrub clean the flue gases of any pollutant gases or particles that may

remain after Bag Filtration System. The Scrubber therefore requires a pump,

pipeline and a retention tank.The size of the Scrubber depends upon the

capacity of the system being installed. Flue gases are introduced in the

body of theScrubber from side and as they move up towards the top of the

Scrubber which has the outlet,

they pass through a spray of fine water droplets provided by a spray shower

provided in the body. This fine spray leads to scrubbing of any pollutant in

the flue gases. Cleaned gases escape through the top opening after passing

through a mist eliminator whereas water with pollutants moves to the bottom

of the Scrubber from where it is passed into the tank. One or more chambers

of the tank allow for settling of pollutants which are then periodically

cleaned and fresh water is added to make up any loss in quantity of water.It

is then recalculated to the Scrubber.

[Note: Due to continuous up-gradation in technology, specified &

projected values may differ in actual products.]

Stack (Chimney)

The generated gases are passed into atmosphere

after treatment through chimney of suitable height and diameter.